Perpetis flexo

Flexo plates automation

Perpetis Flexo has been designed to simplify work and reduce the likelihood of potential human error in flexo printing plates production. This machine is capable of focusing the objects on the plates with considerable amount of automation. Subsequently checking the dimensions correctness, selecting the appropriate cutting parameters according to the type and thickness of the plate, and optimizing the cutting method. Optionally marking the plates according to the customer's wishes.

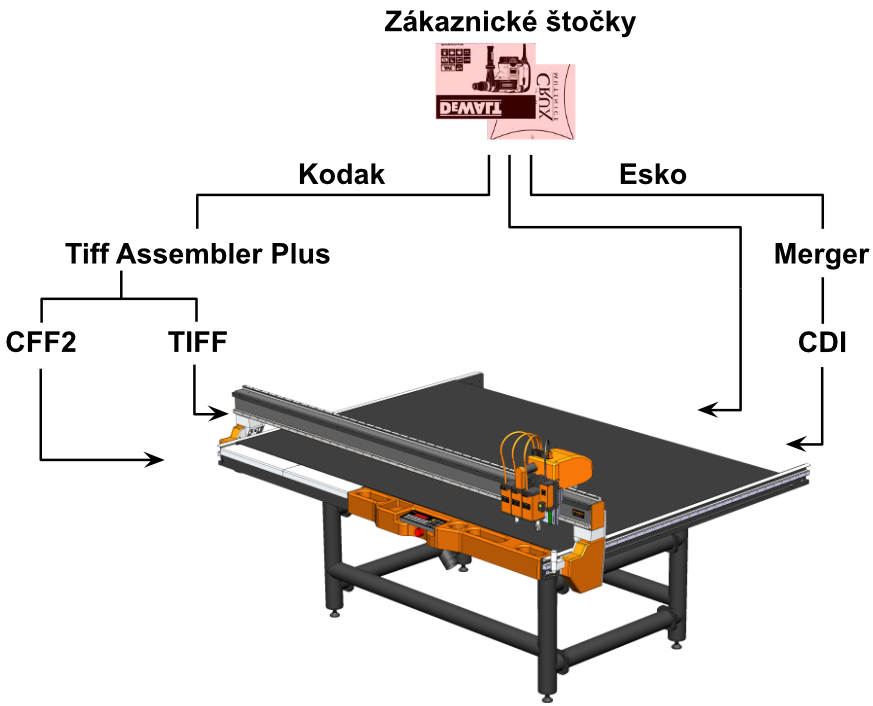

The machine software is striving for highest possible utilization of the flexo CtP imaging units from Kodak (Miraclon) and Esko graphics. This means there is no need for large investments in additional software. Perpetis is therefore also suitable for smaller companies and companies producing printing plates only for their own use.

To streamline the automated process XML files can be used for further control. XML files can be created by a number of information systems and / or automation systems such as the Automation Engine from Eska. Integration into a large system with several Kodak and Esko exposure units is also possible.

Brandeis technologies considers workflow based on XML files to be promising and aims to further develop it to further increase the degree of automation, quality control and the production process. In the future, monitoring the status whether the flexo plate is already discarded or cut should be available. Measurement data, photographs of test wedges, registration and other useful information should be available too.

Trial operation of software for automatic processing of single-bit tiffs is currently in progress. The system maintains the metadata required to use ABS. There will also be software available for dividing TIFs intended for corrugated fiberboard and their further processing on Brandeis or Heaford and Dupont machines.

Kodak and CFF2

Tiff Assembler Plus is a tool for mounting of flexo plates on the final size of material for the CtP imaging unit. It is an integral part of the Kodak Flexcel device.

Perpetis allows output to ACM (Esko Artios Cad Manufacturing) or CFF2 (Common File Format) formats for subsequent division of plates. CFF2 is a more open structured format, allowing further data processing. We do not recommend using the ACM format for working with flexographic printing plates. However, it can be loaded, but it is not currently supported by the cutting import optimizer. It is necessary to insert fitting marks into the assembly during editing.

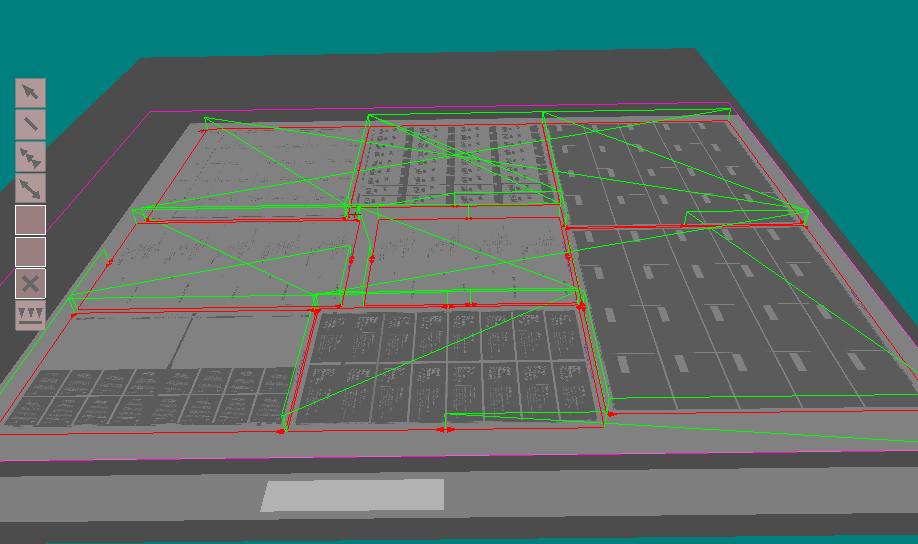

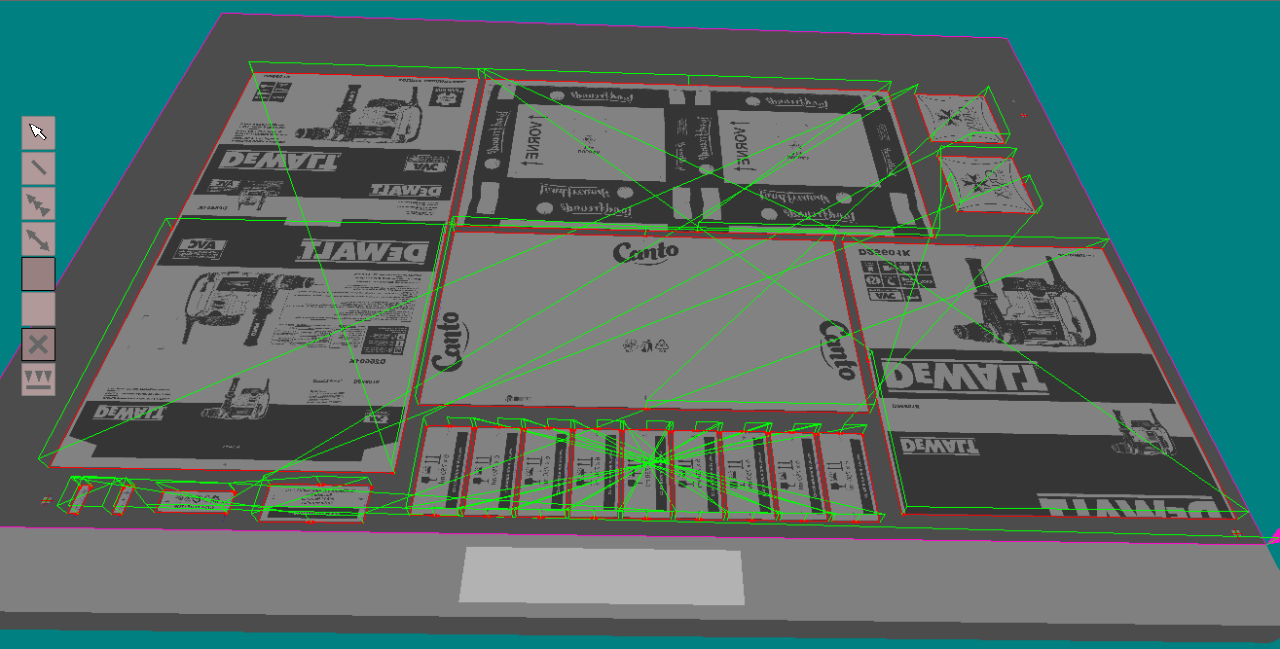

For the actual cutting, it is sufficient to load only the CFF2 file. Based on the information contained in the CFF2 file, the import module reads the plate type and thickness. Depending on the plate type, the cutting speed and acceleration settings are selected. The settings of the camera and the mark recognition module are also part of the so-called "material file" settings. The vacuum zone is automatically selected and the fitting marks are loaded.

The next loaded file is the image data. In the case of TAP it is the discarded Tiff for the CtP imaging unit. This tif has a high resolution, which is further differentiated depending on whether the Digicap function is used. During the import, the tiff is reduced to a preview and placed on the desktop. The information about the motif is excellent for the service orientation. Perpetis will also find a place in it to mark the plate. Loading is fast and takes place in a separate program thread, hence it does not delay the beginning of work. Print data can be entered as a text string directly in the file name or using XML.

Esko and CDI

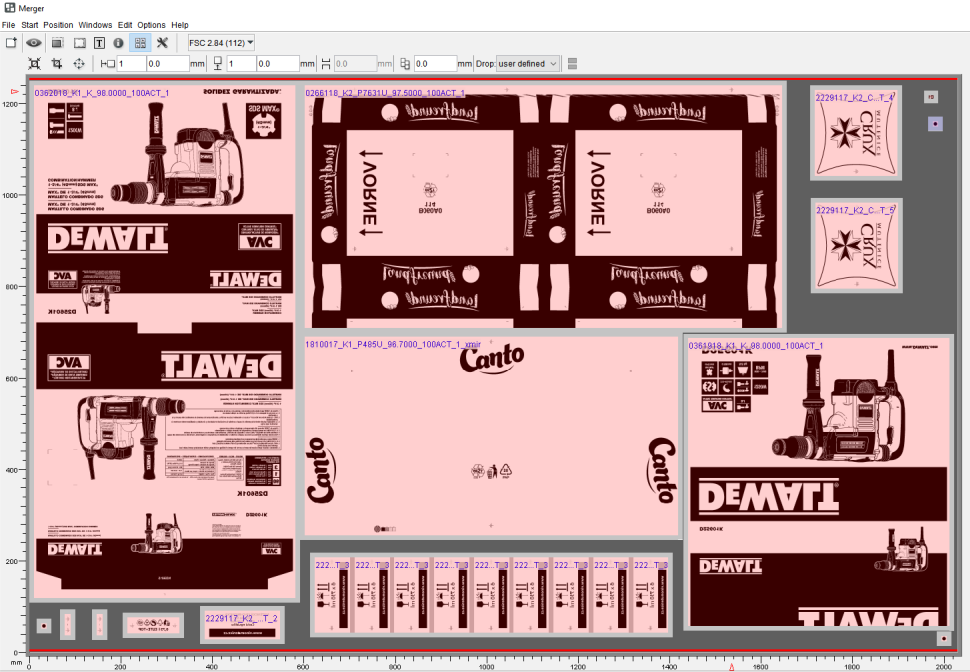

Merger is a tool for mounting plates on the final dimension of material for the CtP imaging unit. It is the basic software of the CDI CtP imaging unit from Esko Graphics company. The CDI file is primarily intended for plate imaging. However, it contains all the data needed to divide the plates, as well as the names of all the included tiffs.

It is necessary to insert fitting marks in the shape of a circle into the assembly during editing. The system recognizes circles of any diameter, which was previously specified. We recommend placing the tags manually in free spaces as needed. The randomness of manual placement of tags pays off sometimes. The machine then evaluates the theoretical and actual distances of the marks. In the case of plates exchange, the randomness of their placement is perfectly suited, making the confusion of files and plates of valuable material impossible.

Brandeis software supports the use of all the functionality of the Merger program. Printing plates can be rotated, mirrored, cropped or multiplied. In order to achieve the same functionality as with TAP, it is necessary to locate the original individual tiffs. File names and XML files or directory structures can be used for this purpose.

For the actual cutting, it is sufficient to load only the CDI file. Plate type and its thickness are stored within the file and are entered into the plate editor. Depending on the material type, the setting of cutting speeds and acceleration is selected. The settings of the camera and the mark recognition module are also part of the material file settings.

In case of CDI, Tiffs are loaded from the original folders. One printing plate usually contains blocks from multiple orders, often so for multiple customers. During the import, the tiff is reduced to a preview and placed on the desktop. Print data can be entered as a text string directly in the file name or using XML.